How to Sew Leather with a Heavy Duty Industrial Sewing Machine

TuffSew here, your heavy duty sewing machine supplier. So, you have decided to start sewing leather. Here at TuffSew, we get one or two questions a day regarding sewing leather.

The most important question to ask yourself is “what sewing machine am I going to use?” Let’s say you have a regular household sewing machine that you plan on using for this leather project. Will it sew your new leather project? The answer is maybe. There are many variables you need to be aware of.

First, your household sewing machine takes a maximum needle size of 19. Will this handle some leather? Yes, it will. But that size needle is pretty thin….and will only work on SOFT leather products with thicknesses from 1/16″ to 1/8″.

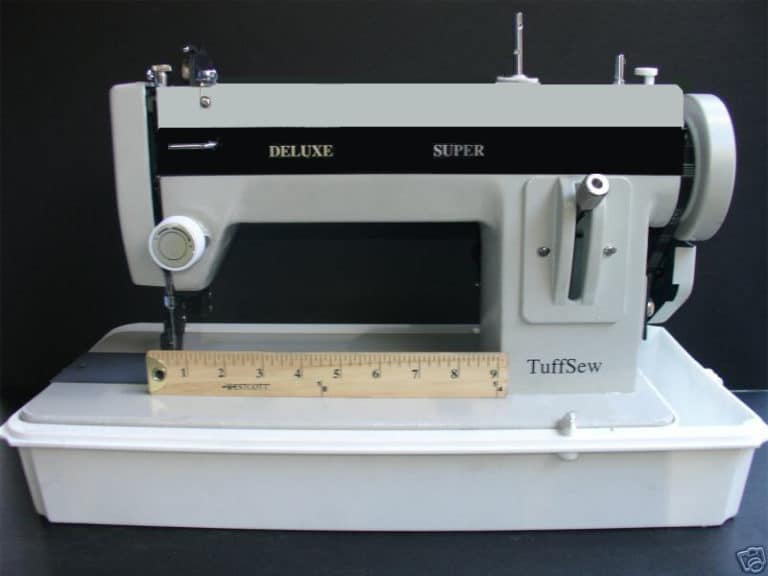

One of the biggest problems people have when using a household sewing machine for leather is they think they can sew 1/4″ thick or greater. If you do this, chances are you will break needles, skip stitches, and stall out. If you truly want to learn how to sew thick leather up to 1/4″ thick, make sure to research machines such as our Straight Stitch Industrial Portable Sewing Machine for leather.

The Straight Stitch can take up a size 23 needle! This size needle looks and feels like a nail…and will penetrate your leather projects very efficiently. This machine is manufactured with a built in walking foot.

This walking foot will grab your leather material from the top and the bottom…evenly feeding your thick material through the sewing process. Here is an image of the walking foot:

And here are the 7 additional tips when sewing leather:

1) Don’t buy the most expensive leather the first or second time you sew leather.

A lot of times you can find scrap leather from a local dealer at very high discounts. Remember, practice makes perfect. Learn how different thicknesses of leather need different needle types, sewing speeds, and varied lengths of stitches.

2) Find a knowledgable leather supplier, someone you can trust.

Give them detailed instructions on what your application or project is, and ask them what they recommend you use.

3) Use a rotary cutter to cut your leather skins.

You should also be using some weights to keep your material in place while you cut.

4) Sewing Leather takes time, slow down.

If you don’t have enough time for your project, then don’t start it. Manage your time and start back up when you can give 100% of your attention and effort to your leather sewing project.

5) You can press leather with an iron (other side of hide).

6) Don’t use pins on leather as they leave holes.

Ask your leather provider about clips.

7) If you are sewing 1/8″ thick or greater, make sure and use a presser foot that is grooved.

The TuffSew Straight Stitch Machine has this grooved presser foot. The feed dogs are also grooved. This will give you the benefit of true grip when you are sewing. You want to be in complete control when sewing thick leather- so make sure and get the right machine for the job. For more information regarding this machine, please visit: Walking Foot Sewing Machine for Leather.

Lastly, here is a YouTube video on some advantages of using a walking foot machine for sewing leather or other thick materials:

Click for more information about our: TuffSew Portable Walking Foot Sewing Machine.

The TuffSew Team