How to Sew Heavy Duty Nylon Materials

Tuffsew here, your heavy duty sewing machine manufacturer. If you are landed on this article, you are probably an outdoor enthusiast looking to make or repair your own gear. I don’t have to tell you that it’s a great feeling telling your friends that you “did it yourself”.

Before creating TuffSew.com in 2003, I was in the sewing business for over 35 years teaching and educating those who wanted to learn how to use a sewing machine.

Over the years I received many questions on sewing heavy duty material including nylon.

In this article, I will go over a few tips that will help you tackle your heavy duty nylon projects.

How to Sew Nylon Materials

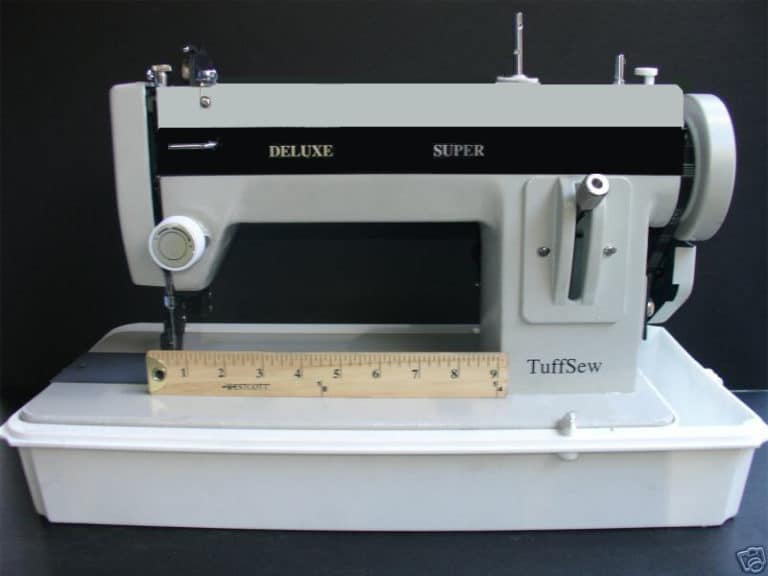

Selecting the Correct Sewing Machine

The first, and most important, part of sewing nylon is to select the correct sewing machine. If you are sewing multiple layers of nylon material you’ll want to use a semi-industrial or industrial sewing machine. More specifically, a walking foot portable industrial sewing machine.

When sewing multiple layers, a built in walking foot helps grab your material from the top and the bottom- efficiently pulling your material evenly through the sewing process. Click the video below to learn more:

Small Details Make a World of Difference

Make sure your sewing machine is cleaned and oiled.

I also recommend you use a size 22 needle (one that’s new and sharp). You should be able to comfortably sew 1/4″ thick (or a tad more) with either a straight stitch or zigzag walking foot sewing machine.

Moving on to thread- very important. When you are sewing heavy duty fabric you are going to need stronger thread.

I would recommend you use nylon bonded (funny eh) #69 thread. Another reason I recommend you use a heavy duty walking foot sewing machine is because bobbin cases on a standard home sewing machines do not allow for the extra thickness of thread. You’ll just keep on getting those rats nests.

Now that you have the right tool for the job- make sure you start off slow. Practice, practice, practice. Use some old scraps of material to get warmed up for your big job.

Make sure your foot pedal works fast and slow. Nothing is worse than using a sewing machine that can’t slow down due to a 1960’s foot pedal.

Well there you have it- I hope I could help get you started with your current nylon sewing project.

Like I said, I’ve been in the sewing industry for over 35 years. If you have any further questions, please don’t hesitate to email me at [email protected].